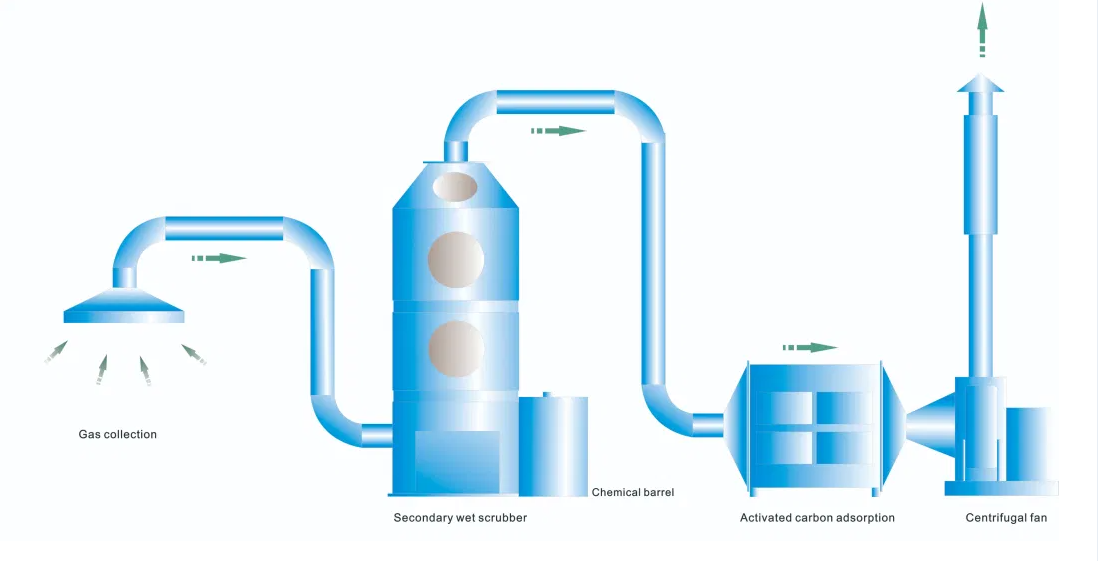

668-Exhaust extraction device system

A washing tower is also called a spray drench tower, according to the size of the tower and the need of processing exhaust gas in the internal device, one or multi-layer spray device will be installed, which has the effect that filtering exhaust gas.

High efficiency in dust removal and desulfurization.

The equipment occupies less space and it is easy to install.

Low energy consumption.

Corrosion and wear resistance.

Stable operation, easy maintenance.

1) The working principle of the most commonly used industrial wet scrubber is countercurrent spraying: acid or alkaline acid mist exhaust gas is introduced into the purification tower through the air duct, and the exhaust gas is fed from the bottom of the tower through the packing layer. continuous through the voids of the packing layer. On the surface of the packing, the gas-liquid two phases fully contact, absorb and neutralize the reaction, and adsorb the acidic or basic pollutants contained in the exhaust gas.

2) After the acid mist exhaust gas is purified, the clean gas is dehydrated and demisted by the defogging plate and then discharged into the atmosphere by the fan.

3) Insoluble viscose particles and dust are poured into the collection tank, suspended particles are discharged from the overflow outlet, and the collected sediment is discharged from the sewage outlet. The absorption liquid is pressurized by the water pump at the bottom of the tower and sprayed downward from the top of the tower, and finally refluxed to the bottom of the tower for recycling.