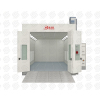

Spray Booth for JZJ-FB-9

|

Outside Dimension (mm) |

9146*6400*4100(L*W*H) |

Inside Dimension(mm) |

9000*4500*3500(L*W*H) |

|||

|

Front Door(mm) |

3300*3400(W*H) |

Service Door (mm) |

800*2000(W*H) |

|||

|

Total Power |

19KW |

|||||

|

Cabin System |

Wall panel |

70mm EPS sandwich panel, steel sheet thickness: 0.426mm |

||||

|

Ceiling panel |

0.8mm Galvanized steel sheet. |

|||||

|

Basement |

350mm depth, full galvanized grids basement |

|||||

|

Ramps |

4 pieces 2500*900mm ramps |

|||||

|

Windows |

5mm safety tempered glass |

|||||

|

Air Make-up System |

Air Inlet fan system |

2*7.5kw centrifugal fan YDW5.6M |

||||

|

Exhausted fan system |

1*15kw centrifugal belt drive fan 4-82-6.3E |

|||||

|

Air capacity for fresh air |

36000m3/h |

|||||

|

Air capacity for exhausted air |

36000 m3/h |

|

|

|

|

|

|

Air Control method |

One manual damper forexhausted system |

|||||

|

Exhausted ducting |

6meters straight ducting, one 90°elbow and one 45°elbow |

|||||

|

Purification System |

Pre-filter |

G3 grade. Pockets filter. |

||||

|

Ceiling filter |

EU5 / F5 |

|||||

|

Floor filter |

Green fiber glass filter / G3 grade |

|||||

|

Exhausted fan filters |

Pocket filter and active carbon |

|||||

|

Heating System |

Heat exchanger |

SUS304 material, argon arc welding. |

||||

|

Heating burner: |

Riello RG5S diesel oil burne |

|||||

|

Heating productivity |

260000Kcal/h |

|||||

|

Spray to baking switch |

20N BELIMO brand electrical damper |

|||||

|

Chimney ducting |

6 meters stainless ducting and one chimney elbow |

|||||

|

Max heating temperature |

80℃ |

|||||

|

fuel consumption |

10-12L/vehicle |

|||||

|

Lighting System |

Ceiling lights |

12Units, each 4 x18w LED lamps ,Total 864W |

||||

|

Side lights |

12Units, each 2 X 18W Philips lamps, Total 432W |

|||||

|

Illumination |

900LUX |

|||||

|

Controlling System |

Switched control panel |

Spraying&baking switch, lighting switch, emergency stop, breakdown alarm, failure alarm |

||||